Discovering the Subsoil: Development of an Intelligent Measurement and Simulation System for Studying Soil-Tool Interactions

Introduction

The efficiency and sustainability of agricultural tillage greatly depend on the precise understanding and optimization of interactions between the soil and tillage tools. In recent years, the application of numerical simulations and machine learning has enabled a deeper investigation of these interactions, contributing to the advancement of tillage processes. This article aims to present the development of an intelligent measurement and simulation system designed to study soil-tool interactions.

Optimization of Tool and Tillage Design

Optimizing tillage processes requires fine-tuning tool geometry and tillage parameters through numerical simulations and machine learning. Numerical simulations facilitate the modeling of various soil structures, moisture content, and porosity effects. Machine learning algorithms can generate predictions based on real data, significantly accelerating and enhancing the design process’s accuracy.

Modeling Different Soil Structures

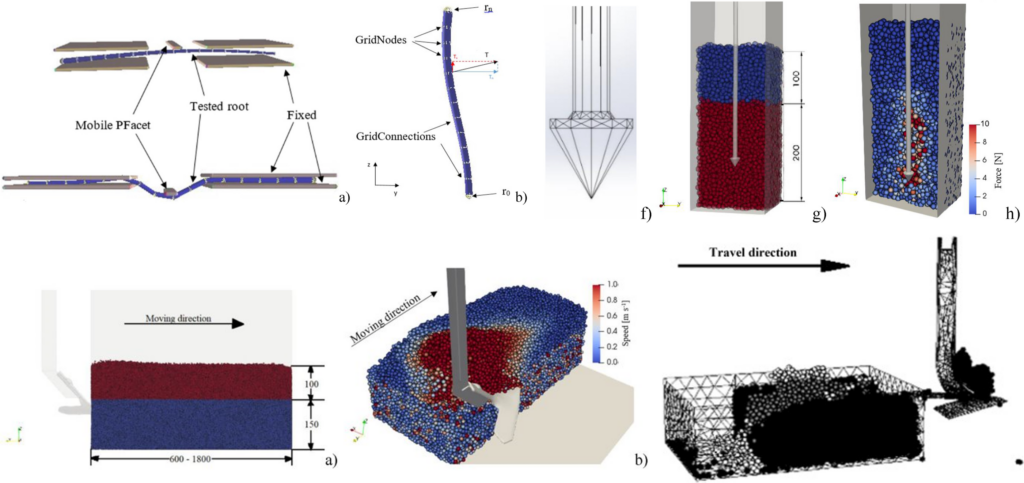

Modeling soil structures through numerical simulations involves considering parameters like soil moisture content and porosity. Techniques such as the Discrete Element Method (DEM), Smoothed Particle Hydrodynamics (SPH), and Finite Element Method (FEM) enable detailed examination of soil-tool interactions. These methods approach the problem from different perspectives, and their combination can result in a comprehensive, high-performing model.

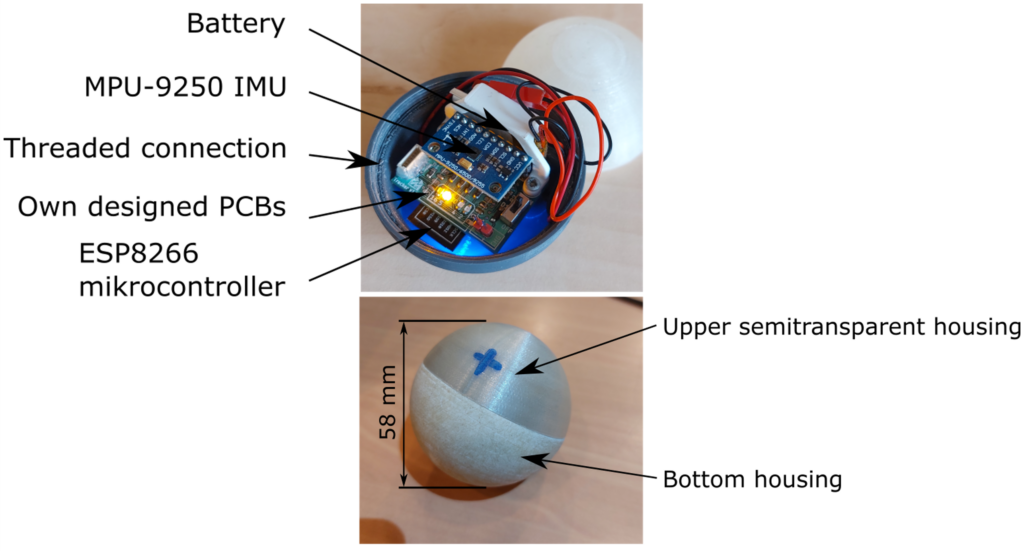

Field Measurements and Hardware Development

A crucial aspect of the development is conducting field measurements in both laboratory and real-world scenarios. The collected data forms the foundation for developing numerical models and machine learning algorithms. This requires designing and manufacturing specialized measurement tools, including circuit and housing design, as well as utilizing additive manufacturing technologies.

FIELD AND LABORATORY MEASUREMENTS

Software Development and Numerical Modeling

The development of the system’s software components ranges from low-level programs close to the hardware to AI-based data processing software. Machine learning algorithms used in data processing enable the efficient handling of field measurement data and the refinement of numerical models. The self-calibration of numerical models is achieved through genetic algorithms, which automate the calibration of model parameters based on laboratory and field tests.

DESIN OF PCBs

NUMERICAL MODELLING

Conclusion

The development of an intelligent measurement and simulation system represents a significant advancement in optimizing tillage processes. The integration of numerical simulations and machine learning technologies allows for a more precise understanding and optimization of soil-tool interactions. In the long term, this contributes to enhancing the sustainability and efficiency of agricultural processes, promoting environmentally friendly and economically viable agricultural practices.

Watch our 3-minute introductory video here

University & team

With its regular high-ranking positions (between 200 and 800) Budapest University of Technology and Economics (BME) is among the top universities (2-6%) globally. At the university’s 8 faculties and 76 departments, there are 1,200 lecturers teaching 5,000 subjects and 10,000 courses each semester. In the H2020 Framework Programme BME has ranked #2 among the Hungarian institutions (67 funded projects). The University is an active member of the European Engineering Learning Innovation and Science Alliance (EELISA) European University, the CESAER association of universities of science and technology and the European University Association.

Contact information:

Kornél Tamás, PhD

Associate Professor

Department of Machine and Product Design

tamas.kornel@gt3.bme.hu

References:

- Tamas, K., & Bernon, L. (2021). Role of particle shape and plant roots in the discrete element model of soil–sweep interaction. Biosystems Engineering, 211, 77-96.

- Tamás, K. (2018). The role of bond and damping in the discrete element model of soil-sweep interaction. Biosystems engineering, 169, 57-70.

- Wágner, Á., Szabó, B., Kovács, L., Tamás, K., & Grad-Gyenge, L. (2023). The development of a soil-movement measurement system to create more precise numeric soil models. In 1st Workshop on Intelligent Infocommunication Networks, Systems and Services (WI2NS2) (pp. 83-88). Budapest University of Technology and Economics.